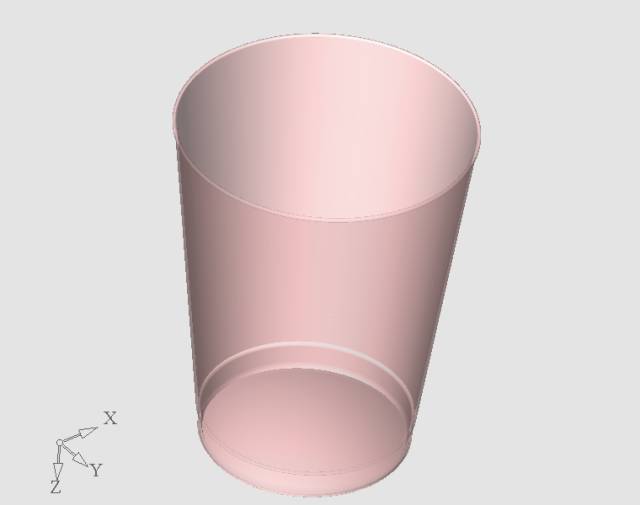

With the progress and development of the times, people use a variety of daily necessities of increased demand, daily necessities mold fast and efficient production methods, to provide people with convenience. In life, water cups, disposable water cups, sports cups and other kinds of containers cups, is a tool for people to solve the drinking water. The mug mold, only need to adjust the material according to the proportion, directly injected into the mold, after it is shaped directly out of the mold can complete the production of a variety of cups, convenient and fast.

Cup mold division is really very simple, is a simple up and down mold, through the past in the use of mug mold, summed up a lesson, in the mold structure, the core can never do insert type, otherwise the concentricity of the dynamic, fixed mold is very unstable. Can not use the “scraper type” demoulding, otherwise the cup mouth is easy to burr, and should be made into independent cavity.

Since the cups of the products do not allow any burrs, the middle top-out method (molding top bar top bottom) is adopted. The gap between the hot nozzle and the mating gear of the gate insert must not be larger than 0.01 on one side, otherwise the molten plastic will overflow and will seriously damage the wire and hot runner components. The size should not be too tight either, too tight will make the assembly difficult and even break the hot nozzle when dismantling.

A sheath is added during operation to keep the cold extrusion bar from being skewed. The sheath is loosely matched to the cold extrusion bar and the inlet insert, and there are threads at the end of the cold extrusion bar to pull the bar out after operation. When there is no cold extruder, you can also use a hammer to gently beat down.

Another important issue is that the outlet of the sprue insert must leave a straight surface, otherwise the life of the sprue insert will be very short and the inlet point on the product will be bigger and bigger, which will affect the appearance of the product.

Post time: Mar-04-2022