The sweeping robot is a kind of intelligent household appliances. It can automatically complete the floor cleaning work in the room with certain artificial intelligence. However, during the injection molding process of the sweeping robot shell, it is stamped and formed by a mold. The structure of the sweeping robot shell is relatively complex. Using ordinary upper and lower molds is difficult to form at one time, which reduces the pass rate. At the same time, the mold is attached to the product, and the thickness of the product is thin, so that the product is subjected to uneven force during the discharge process, which is easy to damage the product, which greatly increases the production cost. , affecting product quality and reducing enterprise efficiency.

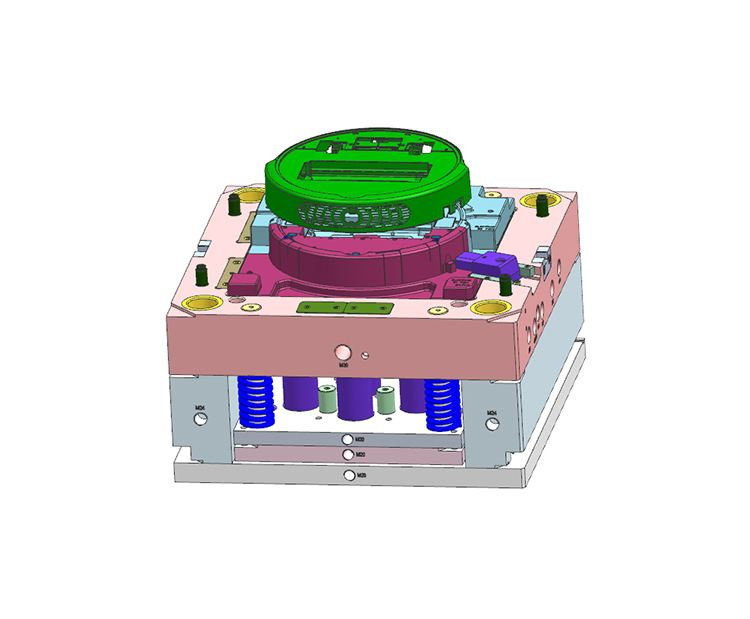

The injection mold for the housing of the sweeping robot can be molded at one time by combining three modules to improve the qualification rate of the product. At the same time, the force is uniform during the discharging process, preventing damage to the product, reducing the high production cost and not affecting the product quality, which can effectively solve the above problems. problems in technology.

1. In order to solve the above problems, the engineers of AJ Mould Company provide technical solutions: the injection mold for the housing of the sweeping robot, including the base, the upper surface of the base is provided with a U-shaped bracket, the inner top side of the U-shaped bracket is provided with a hydraulic column, and the bottom of the hydraulic column is provided with The end is provided with a movable mold, the bottom side of the movable mold is provided with a pressing block, the right side of the pressing block is provided with a slot, the left side of the movable mold is provided with an L-shaped connecting rod, and the bottom end of the side of the L-shaped connecting rod is provided with Strip teeth.

2. Under the U-shaped bracket, there is a support column on the upper surface of the base, the top of the support column is provided with a fixed mold, the upper surface of the fixed mold is provided with a mold groove, and the bottom side of the fixed mold is provided with a circular groove, and the circular The bottom end of the circular groove extends to the inside of the support column, and the front end of the side surface of the circular groove is provided with a rectangular through hole.

Of course, a complete series of professional solutions to the above problems are also required. Read here if you want to know more, please contact us, we will provide you with the best solution.

Post time: Feb-22-2022