-

Hot New Products Houseware Plastic Mold - Chair Mould – Aojie Mould

Our Advantage 1.High quality 2.Reasonable price 3.On time delivery 4.Good After-sale service 5.Strict quality control 6.All the mould are automotic/manual. Chair Mould、Household Products Mould Ao Jie Mold will be glad to provide the quotation and service for you. Production capacity: Mold design, drawing and manufacturing can be done according to 2D drawing, 3D drawing or solid sample. product Details Place of Or... -

China New Product Plastic Chair Injection Mould - Children’s Bathtub Mould – Aojie Mould

Place of Origin Zhejiang, China (Mainland) Brand Name Aojie Mould Shaping Mode Plastic Injection Mould Product Material Plastic CNC Machining Tolerance 0.003to 0.005mm Core & Cavity Material P20, 718,2316… Runner shot Cold or Hot runner Mold life 300.000 shots-500.000 shots. Cycle time 30-50s Delivery time 45-60 days Package STANDARD Wooden case Delivery By sea Different size and shape according to your requirements ... -

Hot-selling Plastic Small Pallet Mould - Crate Mould – Aojie Mould

Crate Mould,Attched Lid Crate Mould This is very difficult for large products, which is the embodiment of our core competitiveness. Place of origin Zhejiang China Brand name LD MOULD Product Material PP /PE/ Shaping Model Injection Cavity Single cavity Design 3D or 2D Runner type Cold runner /hot runner Mould material P20/718 /2738 etc Mould shots 500000-1million shots Sample time 45 -70days Payment terms TT/LC Place of Origin Zhejiang, China (Main... -

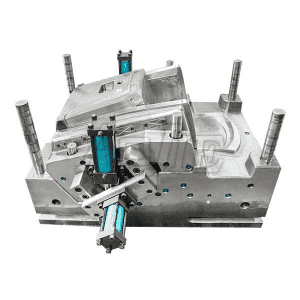

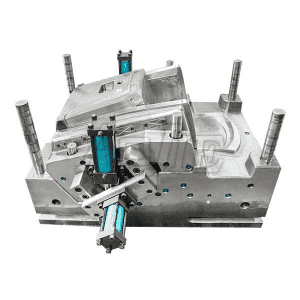

Discount wholesale Moulding Car Parts Mould - Beer Crate Mould – Aojie Mould

Because the structure of beer Crate is more complicated, we adopts beryllium copper insert to shorten the cooling time and pulling structure is used during the injection. Since the beer box is cosmetic part, the deformation of the beer crate plastic parts is required to be small to achieve a convenient mold assembly. There should be no gates or ejection pin trail on the surface of the plastic part. Beer crate mold walls require core pulling and use Ha barking structure in the Four sides. In t...

Hello, come to consult our products !