-

Mold meets process performance requirements

The manufacturing of molds generally involves several processes such as forging, cutting, and heat treatment. In order to ensure the quality of mold manufacturing and reduce production costs, the material should have good forgeability, machinability, hardenability, hardenability and grindability;...Read more -

Advantages and disadvantages of hot runner molds in injection molding

Hot runner mold is currently a more commonly used mold making method. Any material can be processed by hot runner, such as PP, PE, PS, ABS, PBT, PA, PSU, PC, POM, LCP, PVC, PET, PMMA, PEI, ABS/PC, etc. Any plastic material that can be processed with cold runner molds can be processed with hot run...Read more -

About one-third of global mold industry output and consumption are contributed by China

Today I will talk about an article about about one-third of the global mold industry output value and consumption contributed by China Xiangxian. Now I will briefly introduce you to the global mold industry output value and consumption about one-third contributed by China Xiangxian , I hope to he...Read more -

Factors that affect injection molding processing

Injection molding is an industry with a wide range of knowledge, strong technology and strong practicability. Plastic raw materials, toners, nozzle materials, molds, injection molding machines, peripheral equipment, fixtures, sprays, various auxiliary materials and packaging materials, etc., need...Read more -

Mold polishing and maintenance

1. How to control the melt viscosity of ABS? ABS is an amorphous polymer with no obvious melting point. Due to its various grades, suitable process parameters should be formulated according to different grades in the injection molding process. Generally, it can be molded at a temperature above 16...Read more -

The design principle and key points of high-gloss seamless injection mold

Mold material 1. The mold materials required for the surface of the product are available: NK80 (Japan Datong), etc.; 2. Material selection for high light requirements: S136H (Sweden), CEANA1 (Japan), etc.; 3. NK80 does not require quenching treatment; S136H should be quenched to 52 degrees aft...Read more -

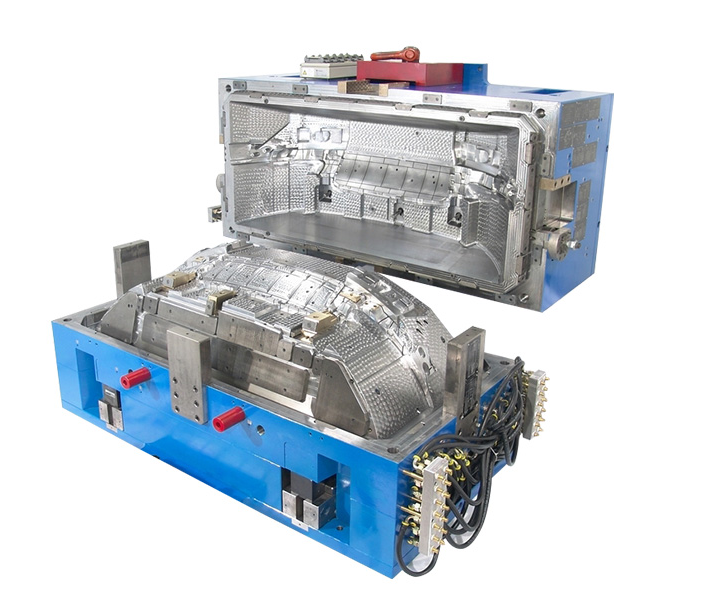

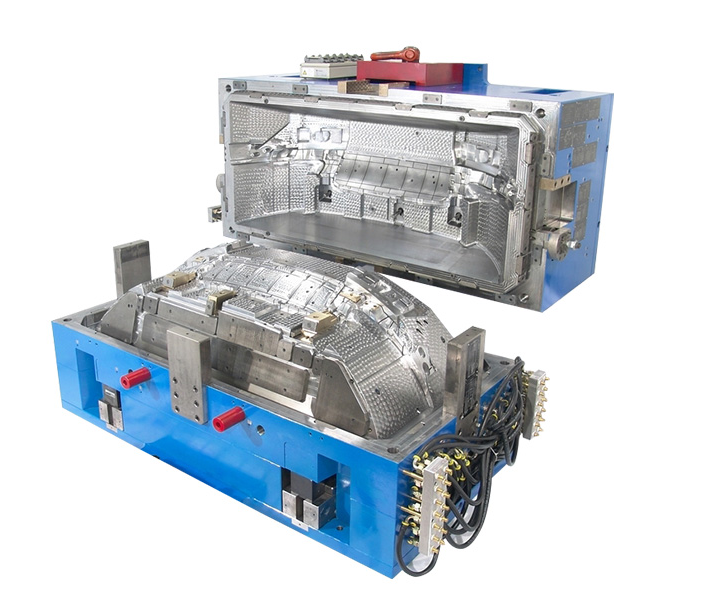

High-gloss seamless injection mold

At present, most of the appearance parts of household appliances are obtained by injection molding. In the injection molding process, defects such as weld marks, gas marks, and deformation are prone to occur; high-gloss non-marking molds can solve the above-mentioned defects. Let’s take a l...Read more -

The influence of injection molding processing conditions on the product

The complexity of the properties of plastic materials determines the complexity of the injection molding process. The performance of plastic materials varies greatly due to different varieties, different processing conditions for producing injection molded parts, different grades, and even differ...Read more -

Mold polishing

In the process of diversification and high-grade development of industrial products, how to improve the quality of molds that directly affect product quality is an important task. In the mold manufacturing process, smoothing and mirroring after shape processing is called part surface grinding and...Read more -

Manufacturing precision injection molding process

Mold opening injection: how to make injection molded parts with processing accuracy. Due to the high fluidity of plastics, it is difficult to produce injection molded parts in strict accordance with the drawings. Especially for some injection molded parts with high dimensional accuracy, the dimen...Read more -

What is the basic principle of injection molded parts processing?

Injection molding means that the trustee presents the raw materials and molds, and the injection molding manufacturer produces injection products in accordance with the trustee’s regulations and deducts the production and processing costs. Injection molding process, also known as injection ...Read more -

What advance preparation must be strengthened for plastic mold trial?

After the plastic mold is produced and processed, the remaining step is to try the mold. What is test mode? To put it simply, look at whether this mold can produce products that meet the standards, and discover the problems of the mold during the test, which is convenient for mold modification an...Read more

Hello, come to consult our products !