Mold is an important process equipment for modern industrial production, which meets the needs of industrialized mass production. Injection mold is a tool for producing plastic products, and it is also a tool for giving plastic products complete structure and precise dimensions. Injection molding is a processing method used in mass production of some complex shapes. Specifically, it refers to the injection of heated and melted plastics into the mold cavity at high pressure by an injection molding machine, and after cooling and solidification, a molded product is obtained.

The structure of traditional injection molds for storage boxes is too fixed to produce storage boxes of different sizes, and the scope of application is narrow, and box-shaped parts and box-like parts are often tightly wrapped on the core due to cooling and shrinkage after forming. , especially for large box parts, in the process of demolding, due to the large force area of the side wall, there is a huge friction between the product and the surface of the core, which makes it difficult for the ejector to eject the product. Ejection, thimble top bend, inconvenient to take out the molded products, more and more unable to meet people’s daily production needs, so we need to design a storage box injection mold to solve these problems.

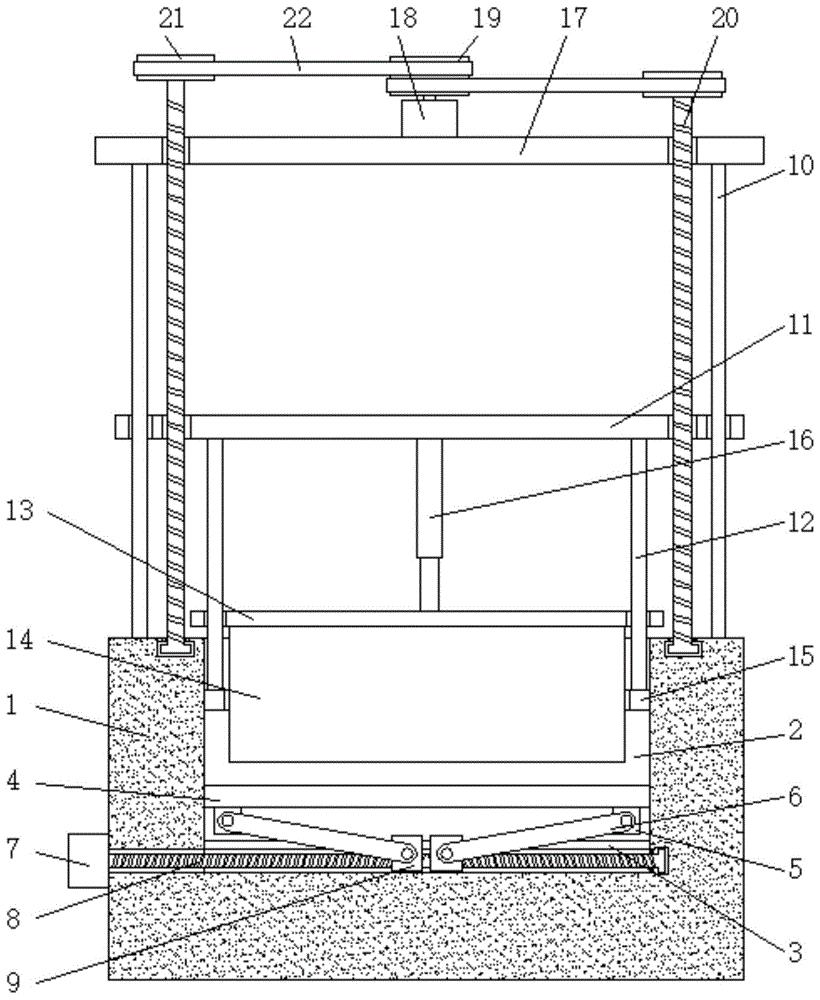

The injection mold of the storage box includes a fixed template, a forming groove is opened in the middle of the top of the fixed template, a partition is slidably connected to the inside of the forming groove, a fixed plate is fixed on both sides of the bottom end of the partition, and both sides of the fixed plate are A rotating rod is hinged, a first motor is installed at the bottom end of one side of the fixed plate, the output shaft of the first motor is fixed with a bidirectional threaded rod, and two sets of moving plates are threadedly connected to the bidirectional threaded rod. One side of the plate is hinged.

A support column is fixed around the top of the fixed formwork, and a lift plate is slidably connected to the support column. Four sets of guide rods are symmetrically fixed at the bottom end of the lift plate, and a movable plate is slidably connected to the guide rod. Adjusting block, the bottom end of the guide rod is fixed with a movable template, the middle of the bottom end of the lifting plate is installed with a cylinder, the piston rod of the cylinder is fixedly connected with the top of the movable plate, the top of the support column is fixed with a top plate, and both sides of the top of the fixed template are fixed. A one-way threaded rod is rotatably connected, and the top end of the one-way threaded rod penetrates through the top plate and is fixed with a driven pulley.

Post time: Feb-25-2022